WHAT IS OUR MODEL?

Apprenticeship2020 is a youth apprenticeship program, which follows the US National Registered Apprenticeship Program that is modeled after European dual-education training programs. Paid, hands-on training at industry partner companies is combined with college education, hence dual education. It is open to youth between the ages of 16 and 24 years of age who have completed high school with an average GPA of 3.0.

The program is well-suited for students who may not desire a four-year college degree but who enjoy working with their hands. Those students can receive training to acquire skills in specialized fields such as Tool & Die Manufacturing, Industrial Maintenance, and Quality Management.

The program offers benefits for students, schools, and companies:

In addition to a fully paid scholarship with the local community college, students in this program receive paid training at hago Automative Corp. At the end of the program, the participants will have earned an associate degree in their specialty field and will have 8,000 hours of hands-on training, which earns them a registered apprenticeship certificate (also called a Journeyman’s Degree). Completion of this program provides participants an education that is sought after by companies worldwide.

Industry partners get access to motivated students who are needed to fill the skilled-trade openings today and in the future. Manufacturing equipment is increasingly sophisticated and requires technical specialists (with hands-on capabilities combined with scholastic knowledge) to build, maintain, and repair state-of-the-art equipment. Only with a strong technical team can the challenges of the future in a global market be mastered

.WHAT TRADE TRAINING IS OFFERED?

Trade training is offered in the following fields:

- Industrial Maintenance

Modern maintenance has evolved into an extensive array of responsibilities ranging from mechanical fabrication, maintenance of production equipment, work on and designing pneumatic and hydraulic systems, electronic troubleshooting, programming of electronic control programs, implementation of visual systems, programming of automatic robotic systems, and design of new equipment and machinery.

Besides physical dexterity, Industrial Maintenance Technicians need to display the ability of logical thinking for trouble shooting complex mechanical systems that consist of fully integrated and interdependent mechanical, electronic, pneumatic, and hydraulic systems. The use of computers and sophisticated programming software is needed for well-rounded Technicians and is required to keep today's production facilities fully functioning.

- Tool & Die Making

Modern Tool & Die Makers use computer-controlled machines to manufacture tooling as well as components that have to comply with tolerances of less than 0.001 inches (less than the thickness of a human hair). The components are then assembled into complex tooling that can weigh anywhere from 200 pounds to 20 tons or more. Each component has to fit precisely in order for the final tool to produce millions of parts by a variety of processes such as plastic injection molding, stamping, forging, or other mass production processes.

As well as physical dexterity, Tool & Die Makers need the ability to think logically in order to trouble shoot complex mechanical systems that consist of, sometimes, hundreds of individual components. Excellent computer skills are required to program the machines using CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) applications. Using these tools, programs are created to run computer controlled machines to mill, turn, wire burn/cut, and laser cut steel components.

- Quality Technician

Quality Technicians monitor production processes, verify the parts are produced within parameters and tolerances, formulate rules, define boundaries, create quality documents, track and analyze production capabilities, and operate inspection equipment required to produce the quality defined by customers. Computer programs and specialized measuring tools are used to maintain set tolerances.

Quality Technicians read and interpret blueprints and define requirements for production of individual components to fit into the final assemblies. This position communicates with all departments involved in the production ranging from purchasing, production, and maintenance all the way to customer feedback.

- Logistics Specialists

Logistics Specialists plan and monitor logistics processes such as ordering purchased material, preparing customer shipments, arranging for all related paperwork, planning production processes, and always keeping an eye on the computer systems and related production and shipping data. Computer programs, in this case an ERP Software (Enterprise Resource Planning Software), are used to track every detail that affects the logistics chain, starting from ordering components, to tracking the warehouse, to planning shipments of produced goods, and finally invoicing the customer. Logistics Specialists have excellent computer skills and understand complex data to be able to plan resources to maintain an uninterrupted supply of produced goods to the customer. This position communicates with all departments involved in the manufacturing process ranging from production, quality, and maintenance, as well as their contacts at the customer to ensure that our ERP System is well aligned with theirs.

HOW LONG DOES IT TAKE?

This registered apprenticeship certificate is a 4-year program requiring 8,000 hours of training. Training is provided according to national requirements at the company and at school. The first two years include dual education, and the last two years focus on hands-on training

.WHAT ARE THE REQUIREMENTS?

Students must maintain a B average in all school work to remain eligible for the program. In addition, students must adhere to company policies and maintain good standing in regard to disciplinary policies (attendance, behavior, documentation, safety, etc) that are applicable to company employees.

ARE THERE STRINGS ATTACHED?

Other than the above listed requirements, there are no strings attached. The partner companies offer training and pay all tuition in excess of any applicable grants that the student qualifies to receive. After completion of the training, the students are free to leave; however, the goal is to have built a relationship that will encourage continued employment

.WHY COMPLETE THE TRAINING?

Even in the depths of the last recession, there were a multitude of openings for skilled trades. These positions cannot be filled with untrained labor; it takes training, knowledge, experience, and discipline to be a skilled technician. Chances are that an apprentice graduate will always have a job regardless of shifts in the economy. These are skilled jobs that are not easily interchangeable

.

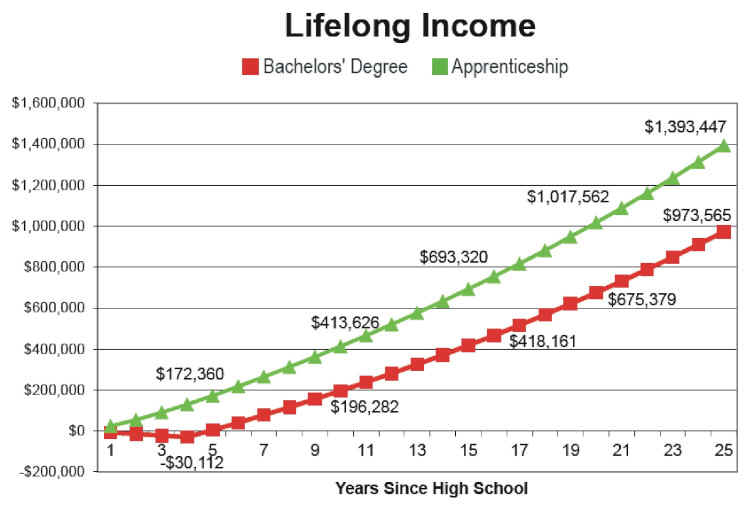

This is free college! The average four-year degree at a state school is $50,000 plus living expenses, and it leaves most students with high debt for many years. A skilled trade job will provide the opportunity for highly competitive wages, and because of the growing need for trades people, hourly wages often eclipse those earned by traditional college graduates. That’s a win-win-win

.

Source: https://dpi.wi.gov/sites/default/files/imce/te/pdf/college_vs_apprenticeship.pdf

HOW TO GET STARTED?

Call us with questions or to schedule a tour with the chance to speak with our current apprentices.

If you are

interested in qualifying for the program, we require an application followed by an

interview.

Please contact us, we look forward to hearing from you.

INDUSTRIAL MAINTENANCE

TOOL & DIE MAKING

CNC MACHINING

QUALITY TECHNICIAN

LOGISTICS SPECIALIST